Understanding the complex world of advanced materials and how they transform defense, energy, biomedical, aerospace, and construction industries — these and many other skills were offered to participants of the course “Advanced Materials Manufacturing”, which started in October at the Kyiv Academic University (KAU) within the Knowledge Rise project.

What is this course about? Who was it designed for, and what background was required? Most importantly — what could participants learn?

Registration via Referral Link

We discussed this with the author of the course, Ostap Zhalat-Lozynskyi, Associate Professor at the Department of Applied Physics and Materials Science of KAU, Deputy Director of the Frantsevich Institute for Problems of Materials Science of the National Academy of Sciences of Ukraine, and Corresponding Member of the NAS of Ukraine.

“This course was more than just learning,” smiled Dr. Ostap. “It was a training program for the future — for those who wanted not only to study materials but also to rethink materiality as a driving force of sustainable progress. It allowed participants to be not just witnesses of technological change, but active shapers of its logic, ethics, and architecture.”

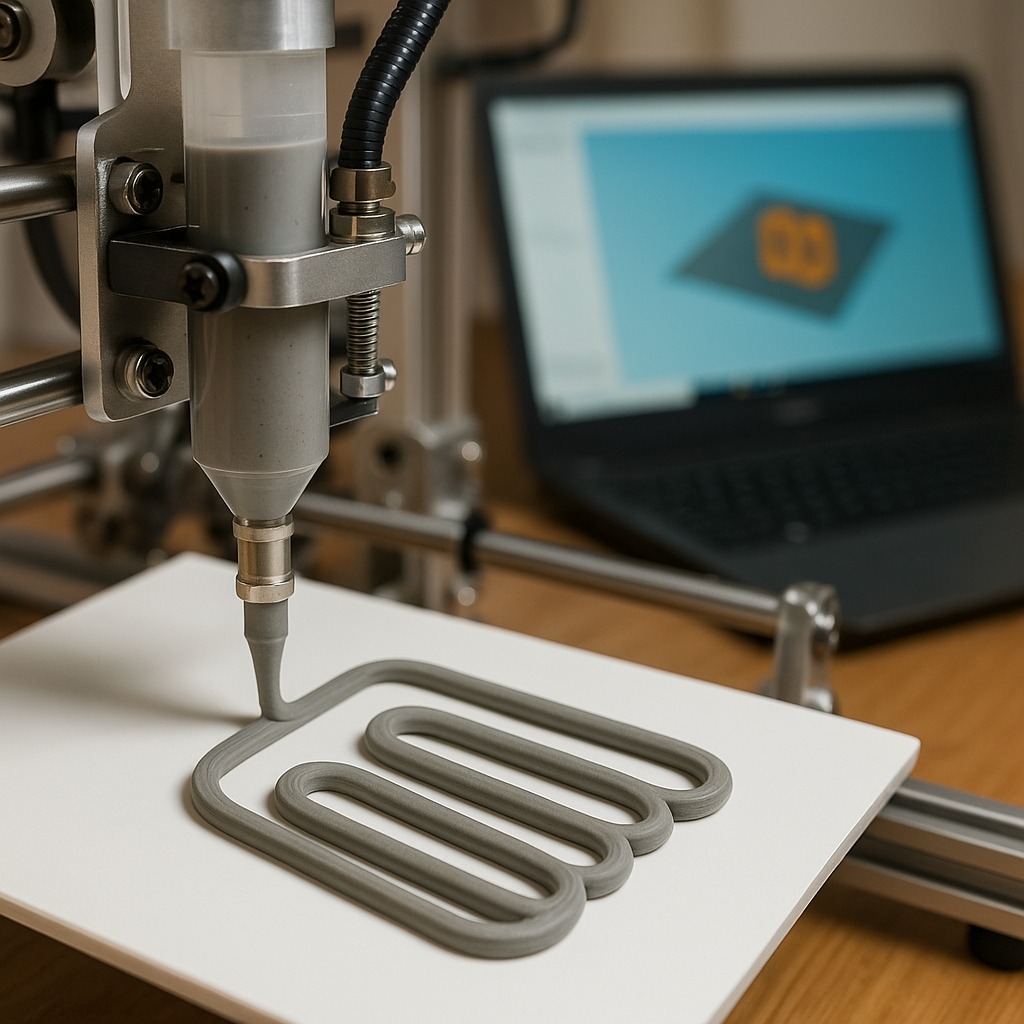

In simple terms, the course focused on materials and materials science — the impact of technologies on the environment and ways to minimize this impact. The lecturer introduced innovative technologies such as electrosintering, microwave processing, and spark plasma sintering, illustrating how these methods were used in research institutes and production environments. He also explained how science-intensive technologies could be implemented in industry.

One way to minimize environmental impact is by extending the lifespan of materials. If a product lasts ten years instead of five, environmental pollution can be significantly reduced. To achieve this, products must be made from so-called “smart materials” — materials with extended operational lifetimes.

“We are currently studying these ‘smart materials,’ and the effects of this research will be felt within five to ten years,” explained Dr. Ostap.

The knowledge gained in this course would become highly relevant in the near future — particularly in dealing with plastic recycling, a global challenge affecting the climate, health, and environment.

“This is also about technologies and materials that can and should be recycled,” he added.

His research team had substantial experience working with plastics and, together with European colleagues, applied for a Horizon Europe grant for research on plastic recycling.

The course consisted of three lectures.

“I taught the material in an accessible way for a broad audience. I hoped to see as many young participants as possible,” said Ostap. “I wanted young people to understand what engineering disciplines are, what opportunities they open, and why materials science is important and fascinating.”

Young researchers could apply the acquired knowledge in developing new classes of materials, optimizing structures through AI and digital modeling, and conducting advanced scientific studies.

Industry specialists could learn how to create scalable, environmentally safe production processes in aviation, energy, construction, and electronics.

Startup founders and entrepreneurs would be able to develop high–value-added products and enter global markets.

“I often hear that investors and business angels are ready to fund new technologies if you have an idea,” noted Dr. Ostap. “That’s why during the course, I explained how to generate ideas in science, build a bridge between business and research, and implement new technologies.”

The course was also useful for policymakers and civil society leaders, as understanding the basics of materials science is essential for shaping environmental and technological policies.

– A systemic understanding of materials through the principle “composition–structure–technology–properties,” integrating engineering logic with sustainable development.

– Deep immersion in advanced technologies, including Smart Manufacturing, TRL management, and Life Cycle Assessment.

– Relevance and strategic orientation — topics adapted to real challenges, with modules on innovation ecosystems, patent landscapes, and commercialization regulations.

– Transdisciplinarity and applicability, combining materials science, eco-design, digital engineering, and market analytics.

“This interdisciplinary course was not just an educational product but a strategic tool for shaping a new generation of engineers, designers, technologists, and researchers capable of managing material transformations of the future,” summarized Ostap Zhalat-Lozynskyi. “It integrated fundamental science, engineering modeling, environmental ethics, and business strategies into one holistic vision — essential for navigating the complex world of advanced materials.”

Prepared by Svitlana Halata